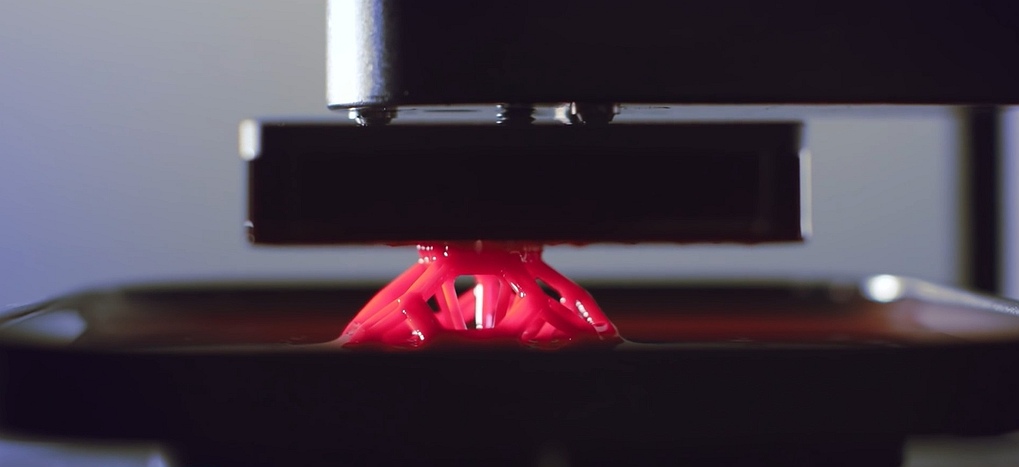

Liquid metal regenerative printing is like when T-1000 melts together in Terminator 2. Seems like the stuff of science fiction but Joseph DeSimone and several other scientists from the University of North Carolina have made it a reality. They founded Carbon3D to sell their new 3D printer that uses something they call “continuous liquid interface production.” (CLIP)

CLIP removes weakness from 3D printed objects by eliminating the need to print in layers as is customary for most 3D printers on the market. This new method actually prints the entire object in a single go by having a platform draw the object out of a bath of liquid resin.

After the print has been initiated, the resin is pulled out by the platform and solidifies when it is hit by UV (ultraviolet light) in a process known as photopolymerization.

To boil it down to the simplest terms:

1) The platform goes into the resin bath and begins pulling out the resin bit by bit.

2) A projector that is below the pool of resin huts the resin on the platform in specific places to solidify those parts and let the rest of the resin drip back into the pool.

3) The object then forms as the platform is pulled slowly upwards making it seem as though the object was always in the pool of resin.

Another advantage beside the extra strength offered by CLIP is that the printing time is significantly reduced. With CLIP, 3D objects can be printed 25-100 times faster than every other 3D printing method.

CLIP technology by carbon3D

This article would be nothing without these screens from Terminator 2.